the nerd 389 :

For an AIO, the radiator material isn't as much of an issue. The loop is much more tightly controlled than open-loop designs. Any engineer worth their salt would ensure that if they use an aluminum rad, the rest of the components will either also be aluminum or galvanically isolated. That's nearly impossible to do in an open loop.

Regarding OLC coolers, the reviews are a few clicks away. The summary is basically that the Celsius S24 handily beats this cooler, and this cooler handily beats the other OLC options.

Lastly, it's fairly easy to check coolant flow without opening the loop. All you have to do is use the CPU power and instantaneous coolant temperature change to derive the heat capacity per minute. That translates directly into flow via mass per second and the heat capacity of water. That's easy if the coolant sensor is before the radiator, but requires removing the fans and wrapping the radiator if the sensor comes after the radiator. It's worth noting that above about 0.2 GPM, coolant flow doesn't really come into play until you push a lot of heat into the loop, and then double up on the fans and run them at full speed.

1. It does matter as copper has better heat transfer capability than aluminum does. Thatz why AIOs w/ copper rads always outperform aluminum ones. See test results below

2. The context here is Open Loop AIOs ... and in this context, your assertion about one being "more tightly controlled" escapes me. How does an AIO from Swiftech (or EK) which comes in a box, pre-assembled from the factory with a copper rad and copper block any more or less "tightly controlled" then ones with aluminum from Corsair or CM ? Why do these copper units crush the aluminum ones at same fan speeds / noise levels ? The have capable pumps and copper rads.

3. Every CLC type AIO does exactly what you say any engineer worth his salt wouldn't do. Every CLC that I have ever seen has these ... er... "features" in common.

a) Aluminum radiator with poor heat transfer compared to copper

b) Aluminum rad and copper block does create a galvanic corrosion cell which is inhibited, for a time, by corrosion inhibitors in the coolant

c) No way to augment those corrosion inhibitors which are effective up to 18-24 months. Can't open the loop to add more.

d) CLCs have grossly inadequate pump flow ... which is why they don't disclose it.

4. There are way too many variables to do the calculation as described.... using that calculation, more flow would always be better which does not prove out in testing so it's obviously flawed. More flow above a certain point adds large increases in head and little increase in flow making the pump itself a significant source of heat. My pump(s) consume about 5 watts (1.25 gpm) under load testing, if I push them to max (2.75 gpm), it's greater than 30... or roughly an increase of 20-25% of CPU load. That 1.25 is more than 10 times the H100i.

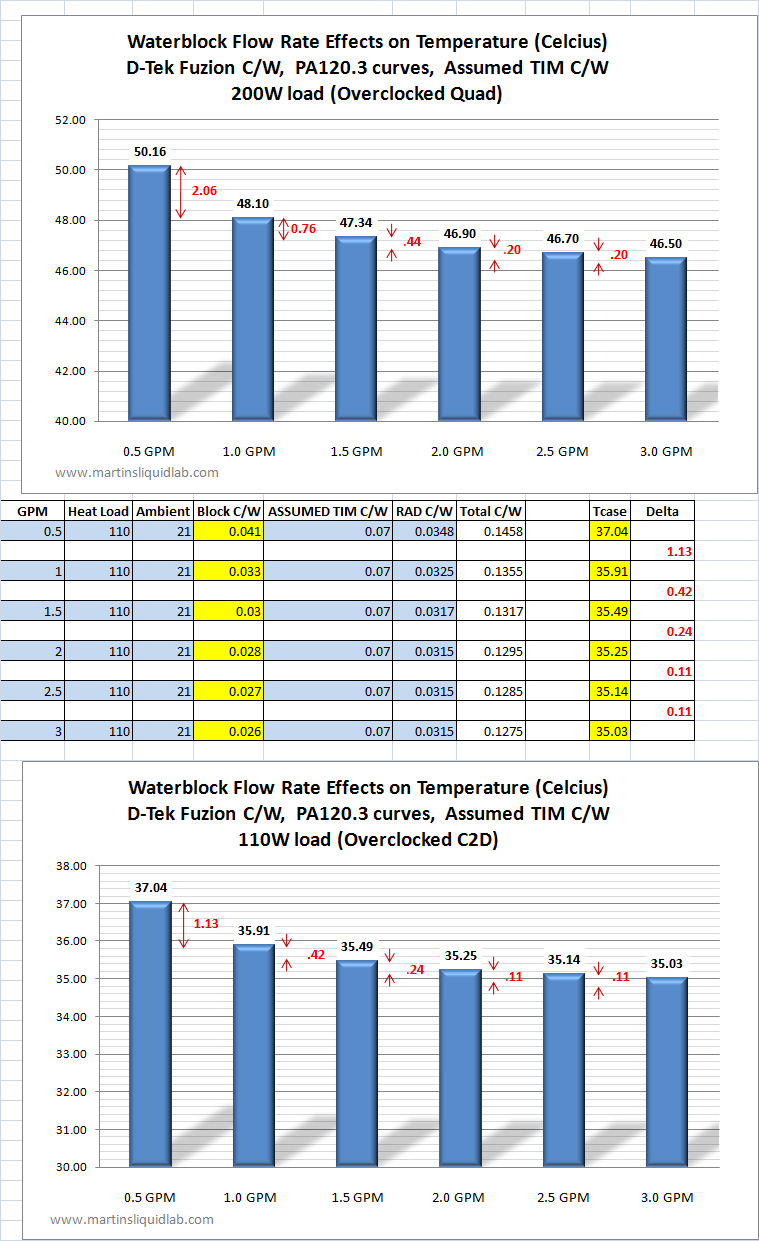

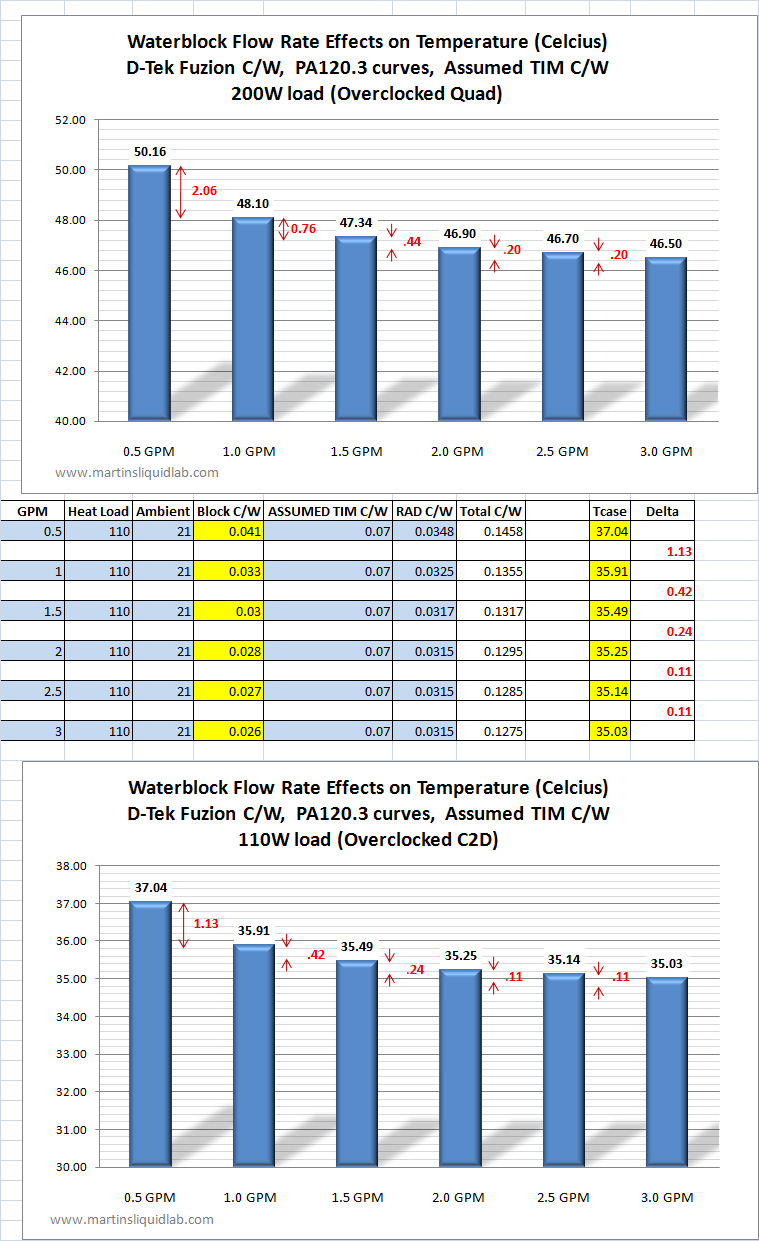

From martinsliquidlab ...as you can see they don't even bother testing below 0.5 ... and look how steep it is from 1.0 to 0.5 ... imagine what 0.1 looks like.

5. If ya read a decent water cooling guide or test from a reputable site, you will quickly see a statement to the effect that flow doesn't matter to much ... once you get above 1.0 gpm. Many sites recommend 1.5 but they seem to be in older guides with rads of higher fpi than we see today. Our test bed includes 2 pumps, 5 x 140mm of rad, 10 rad fans, 6 thermal sensors (one in and out for each rad water temp + ambient / case air) with 6 channel digital display both accurate to 0.1 C and two flow meters. By measuring the water temp in and out of each rad, we can graph Delta T by fan rpm and flow ... over 1.25 gpm its getting pretty flat ... temps improve substantially w/ increased flow up to 1.0 gpm and show a more moderate increase from 1.00 to 1.25....after 1.5, it is a straight line. The Corsair H100i, when opened and tested, produced a wholly inadequate 0.11 gpm.

6. The "few clicks away" comment makes no sense as if that's the reasoning, why compare anything ? When choosing a cooler, the things folks should be able to walk away with an understanding of ...

- Is this going to be cooler / quieter than a comparably priced air cooler (no)

- Does it have mixed metals ? (yes)

- Does it have adequate flow rate ? (no)

Look here (25:14) and we see the Swiftech H240-Xcooler w/ copper rad at idle speeds compared with everything else at Kraken X61, H100i) at max speed ...With the copper rad, the Swiftech manages the same CPU temp as the X61 all out bawlz to the wall The Kraken has to be maxed out and be 5 times louder to keep up w/ the Swiftech at idle ... you yes, material matters.

https://www.youtube.com/watch?v=PYKdKVxbnp8

Back up to 23;15 and we see that with all units going all out, the H220-X and the Noctua air cooler keep the CPUs substantially cooler ... and for the H100i to lose by 3C to a cheaper air cooler, it has to be 11.3 times as loud as the Noctua. The H220-X is twice as loud in this graph making the H100i more than 5 times as loud as the H100i.