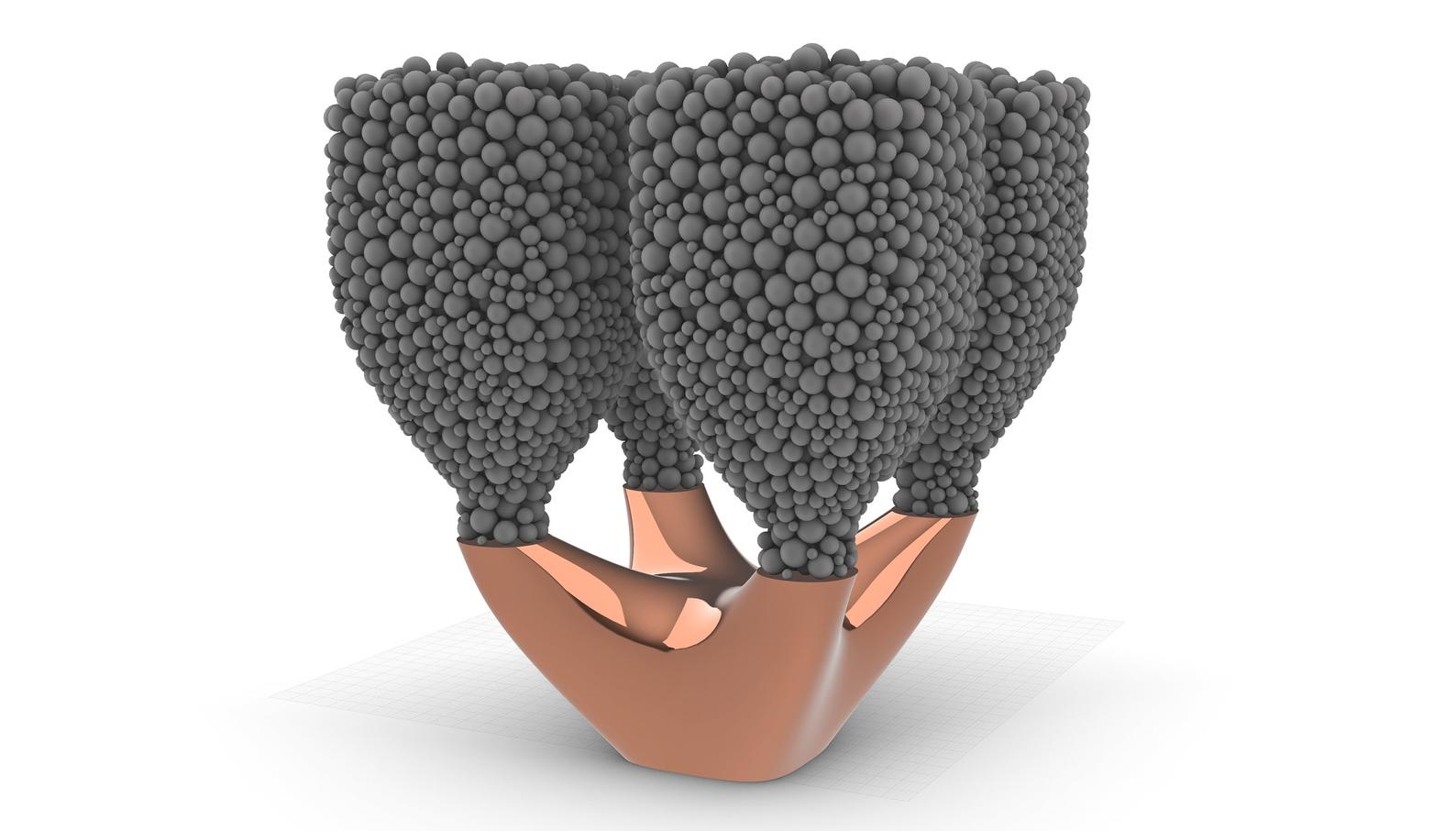

An Intel Core i9 CPU was successfully cooled by an 8lb copper block salvaged from medical machinery, but we aren’t sure how well it would have held up under prolonged workloads.

DIYer Passive Cools Core i9 with 8-Pound Copper Block : Read more

What is misunderstood here is that the copper block is acting only as a "heat sink". It will absorb [sink] heat from the device and at the same time it will lose some heat from its surface area until it reaches equilibrium, i.e., when the heat put in equals the heat radiated or convected to the ambient air from its surface. Then its temperature will rise and thus may not prevent the device's critical junction temperature [Tj] from being exceeded. What we normally refer to as a heat sink is better called a "cooler", its job is to collect heat from the device, conduct it to its fins and allow the heat to escape by a process of convection and radiation to the ambient air.

Heat flows from the hotter body to the colder, it does not flow the other way, and if the ambient air temperature is high the "cooler" becomes less efficient. Mistaking thermal conductivity for cooling ability is a common mistake, Aluminium is preferred for "cooler" manufacture due to low cost, workability and low weight. Copper is a better conductor, Silver is the, but both are costly. Fins are vital to increase surface area, but unless the air is forced air by a fan or blower, must be spaced more than 8 to 10mm apart to avoid radiation between fins. Staggered fins to increase turbulence are better than straight ones as they break up any boundary layers that might occur in the air flow. Way back in the 60's and 70's when devices were much less efficient, many useful "heat sinks" [although better known as coolers] were available. Mostly plain aluminium was used, black anodising was offered, but the improvement gained was not cost effective. Industry tried many alternatives [ebullition cooling, liquid cooling, phase change heat pipes and even thermally connecting the devices to the fuel flow in military aircraft, as an airplanes fuel tanks are a great source of "cool"!

But all methods must move the device's heat to somewhere else. In the extreme you could machine a PC Cabinet from a solid block of copper, machine grooves all over its surface, then crosscut them to stagger them, but if the device's dissipation is more than the cabinet can dissipate in free air, you might have to direct fans at it to help it. The thermal interface between the cooler and the device is CRITICAL. Unless the two surfaces are flat to a very high degree, some interface material, thermal grease, thermally conductive polymers, or metallic loaded elastomeric compounds are necessary.

Just as a reminder, a cooler for a semiconductor device will be rated in what I always called "Thermal Ohms" or more correctly, thermal resistance in Degrees Centigrade per Watt; if you knew the ambient temperature and the device's power dissipation you could easily calculate what size heatsink to use. Lastly it's important to know there are three methods of moving heat, Conduction, Convection and Radiation, most are misunderstood, the first example to come to mind is that here in the UK we heat our houses with water heated by gas or oil, and piped to Radiators, which in fact are not very good radiators at all [because we paint them] but are in fact convectors.