Wow thank you for such a well thought out reply. I will be studying the performance of various types of air conditioners. So I will have six temperature sensors:

Indoor temperature

Outdoor temperature

Outdoor Hot Side Inlet air temperature

Outdoor Hot Side air exit temperature

Indoor Inlet air temperature

And most important the cold air flowing into the room

I'm a mechanical engineer by training and work experience. So I don't have a significant electrical equipment background. I did pretty extensive searching for various types of temperature sensors. A lot of the temperature sensors on Amazon talk about "I2C" Standard format. I had to look that up. Everything I was finding on that clearly presupposed a good deal of knowledge in this area. The link you sent me led to the nearest thing I could find for a beginner.

In searching for temperature sensors, units made for taking data can be fairly expensive. But I found a few hundred of a great variety of types on DigiKey.com, many of them only a couple to a few dollars. I would search the data sheets for what is the output voltage. The vast majority don't say because they don't work that simply. I eventually realized that the reason Those sensors were so cheap was that they go in to Consumer and Industrial Products and are being bought by the thousands. I read dozens of DataSheets and none of them explain how they work.

But I found one that gave me a little insight.

Angst+Pfister Sensor SMT172-TO18

https://www.digikey.com/en/products/detail/angst-pfister-sensors-and-power-ag/SMT172-TO18/17827925

Here's a short paragraph from that sensor's data sheet.

(The SMT172 operates with a supply voltage from 2.7V to 5.5V. The typical active current of only 60µA, the high speed conversion over 4000 outputs per second (at room temperature) and an extremely low noise makes this sensor the most energy efficient temperature sensor in the world (0.36µJ/measurement). The SMT172 has a pulse width modulated (PWM) output signal, where the duty cycle is proportional to the measured temperature. This makes it possible that the sensor can directly interface to a MCU without using an Analog-to-Digital Converter (ADC). Today, the hardware Timer in a MCU to read our PWM signal has become available almost universally, fast in speed and low in cost. Therefore, it is extremely easy for any user to get started with this sensor and achieve a very quick time to market.)

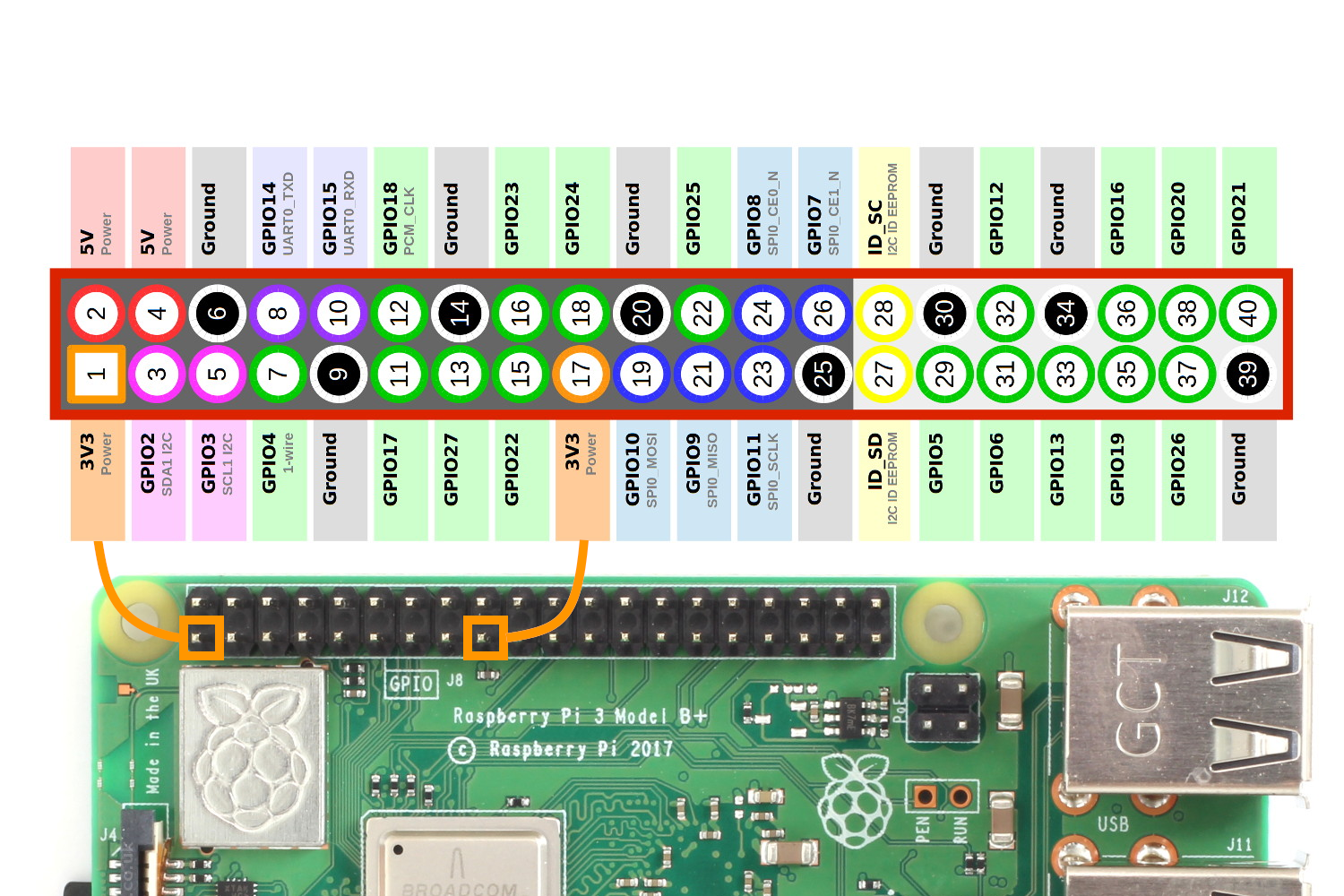

I read enough about Raspberry Pi units to see the references to microcontrollers and see how sophisticated they are not only recording data but controlling other device types. All I need to do is take data.

So I am leaning toward a specific data taking product like the one below.

DI-2108-P High speed USB Data Acquisition system with Windaq software. Measures ±10V at 160 kHz throughput rates. Features 16-bit resolution, stand-alone capability, and 5 programmable gain ranges.

www.dataq.com

I have another project studying the forces on a cylinder and on a sphere dropped into still water. It's just crazy how high the forces are. Water does not like to get out of the way. The force on a cylinder peaks at about 5.5 times the force of that same cylinder stuck in a water flow current the same velocity as the dropped cylinder hits the water. It's why a belly flop can really hurt. For this I need an absolute minimum of 40,000 data points per second to have the initial Force Peak populated by 11 to 121 data points. It's also freaky how soon the force peaks, When only about 5% of the cylinder's volume is beneath the initial water surface. That data logger can do 160,000 per second on one channel, 80,000 on two channels etc.

I'm interested in anything else you have to say or any recommendations you may have.

Thank you!!

Peter McFadden