You need to understand why you're getting what fittings and tubing for very good reasons - they are the linchpin in the entire loop and not knowing what you need can lead to some disastrous results.

From the watercooling sticky (linked in my signature line):

Tubing and Fittings

Tubing can be as generic as the hardware store vinyl tubing at your local Ace Hardware, Home Depot or Lowes or as complex as the Feser, Primochill, Masterkleer or Tygon brands you find online among other watercooling components. Your average hardware store vinyl tubing is typically thin walled and does not make tight radius bends well, while your premium brands are very flexible and come in most commonly used ID and OD tubing sizes for watercooling as well as in many colors. If you are needing some good bends made, consider getting good tubing, but understand most is upwards of $1.50-$2.50 per linear foot.

Fittings are one that cause a lot of confusion for most newcomers. Here is a simple way to understand the terminology that accompanys each:

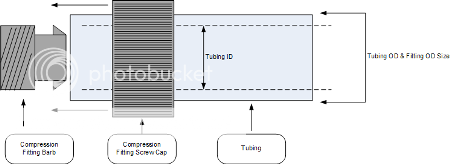

I.D. - Inside diameter, most commonly referring to the ID of the tubing to be used. 1/2"ID means that wall to wall, the inside of the tubing measures 1/2" (metric is also used and is measured in millimeters or mm)

O.D.- Outside diameter, similar to the ID, the OD simply is the measurement of the tubing through the cross-section from one side of the outer wall to the other.

G1/4 - This is the one that confuses the most people. This refers to the threaded fitting standard that is used by almost all waterblocks and radiators. It is the end of the fitting that gets screwed into the block or rad; the other end of this same fitting is measured with the I.D. standard for tubing size. If you are unsure if the threaded fitting size is G1/4 double check before threading the fitting as you can easily cross thread a fitting that isn't using this standard.

Barbs- Barbs are very common and have been used as the primary fitting type in watercooling for many, many years. It offers a threaded end for connection to radiators, blocks and reservoirs and are typically G1/4, but other standard sizes have been used as well. Once the barb is threaded into the applicable port and secured, the tubing slides over the 'barbed' end which help secure the tubing, usually with some kind of clamp for extra precaution. You can also use a slightly larger barb size than tubing size for a more snug fit; ex. 7/16"ID tubing over a 1/2"ID barb. This will require you to dip the tubing ends in hot water to soften in order to slide them easily over the fitting end.

Compression Fittings - These fittings are actually the combination of a barb and a clamp into a fitting that secures the compression ring onto the fitting by threading it down. The threaded end of the fitting is installed as it is with a normal barb, and prior to pushing the tubing over the barb, ensure the threaded compression ring is slid over the tubing with the threads facing the correct way. Push the tubing over the barb and then slide the compression ring down over the barb and thread/secure to the fitting itself. This clamps and seals the tubing in place.