I recently bought a used motherboard from a seller on Amazon and it didn't come with an i/o shield (despite the fact that all of the pictures showed it with the i/o shield and there was nothing the description to indicate that it wasn't included, but that's another story.)

I got a good deal on the motherboard and I really didn't want to send it back. I looked EVERYWHERE for a replacement plate and the only one I could find was from a seller on eBay from the Netherlands and it was going to take about 3 weeks to arrive. I even tried contacting ASUS to see if they could sell me one, but they were no help.

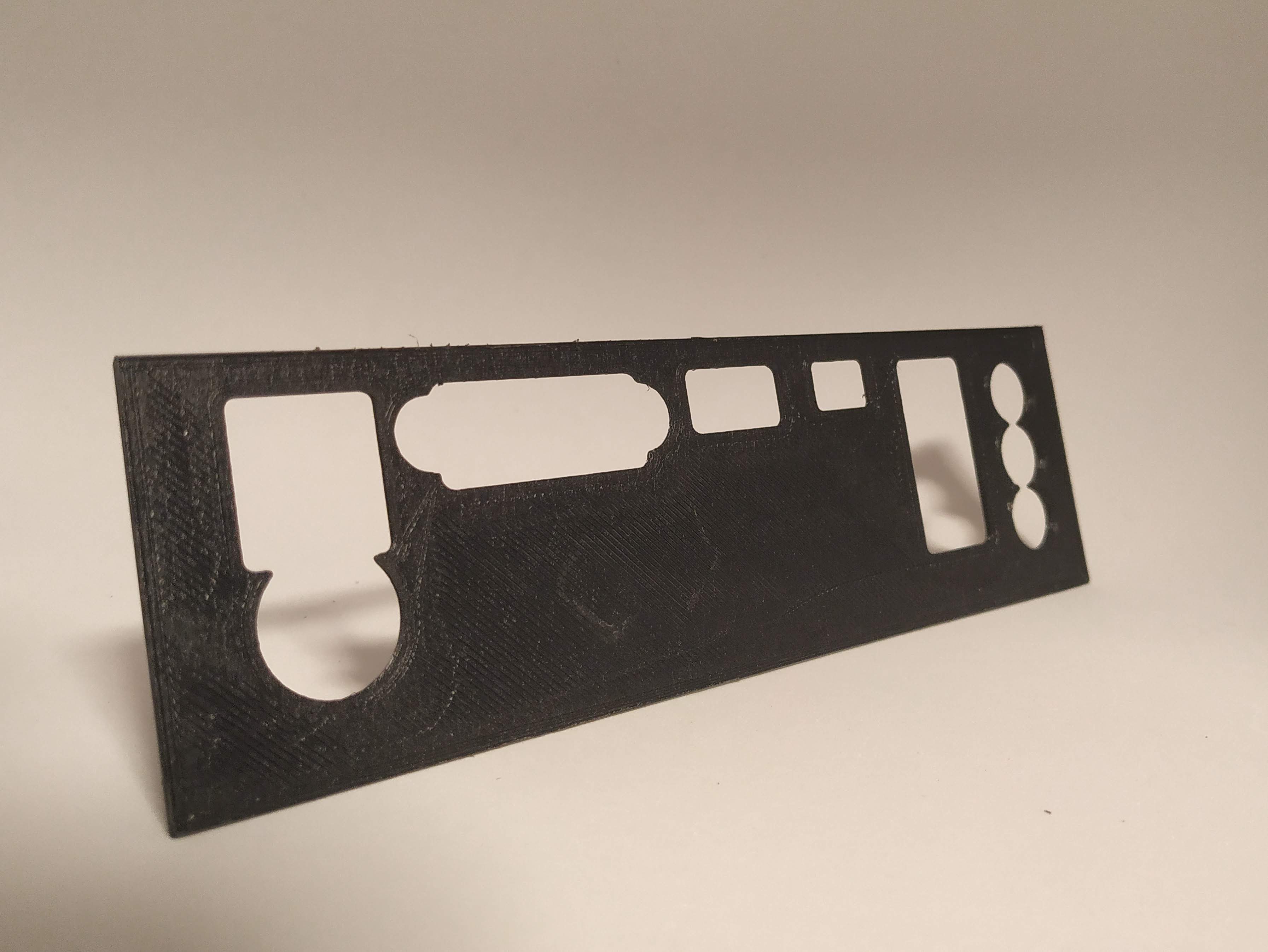

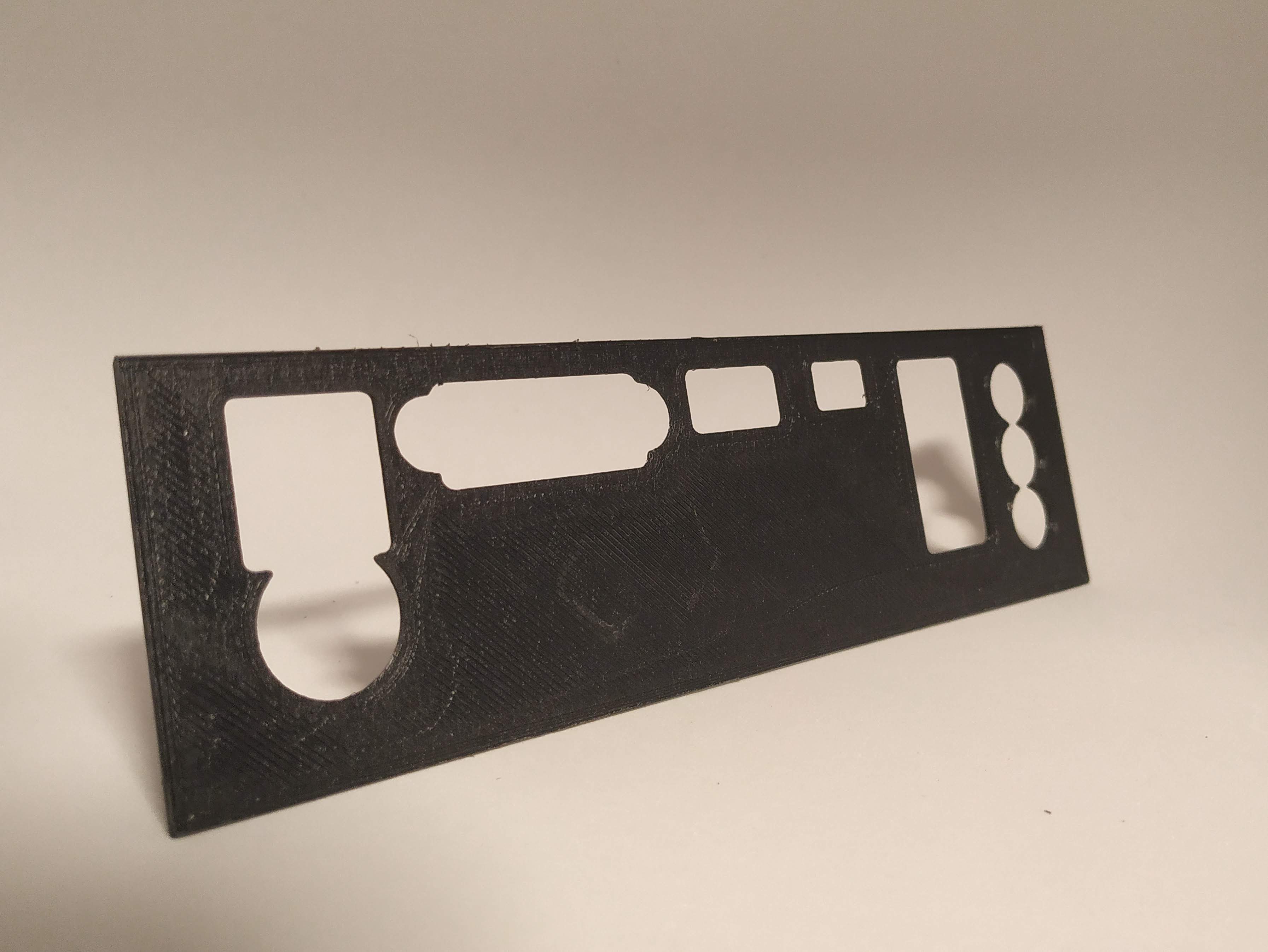

Then, I got the idea to have one 3D printed. I used some free 3D design software and I used the motherboard and as many pictures of the original i/o shield I could find online to make my best guess as to where to put the openings and how large to make them. As you can see in the photo, I gave myself a LOT of room for error. I found a guy locally to print it for me for $15 which is less than it would have cost me to buy it on eBay and have it shipped to me.

So, it came out pretty good and it fits ok, but is there any risk to having a plastic i/o cover as opposed to metal? I know there is some grounding that you get with metal covers, but I also know people who run their PCs with no i/o cover for years and never have a problem. So is there a big risk here? A small risk? Or no real risk at all?

And if there is a risk, what could I do to give this plastic cover the same EM protection that a metal cover would give? Is there something metal that I could stick to the back or something?

Thanks in advance for any advice/suggestions!!

I got a good deal on the motherboard and I really didn't want to send it back. I looked EVERYWHERE for a replacement plate and the only one I could find was from a seller on eBay from the Netherlands and it was going to take about 3 weeks to arrive. I even tried contacting ASUS to see if they could sell me one, but they were no help.

Then, I got the idea to have one 3D printed. I used some free 3D design software and I used the motherboard and as many pictures of the original i/o shield I could find online to make my best guess as to where to put the openings and how large to make them. As you can see in the photo, I gave myself a LOT of room for error. I found a guy locally to print it for me for $15 which is less than it would have cost me to buy it on eBay and have it shipped to me.

So, it came out pretty good and it fits ok, but is there any risk to having a plastic i/o cover as opposed to metal? I know there is some grounding that you get with metal covers, but I also know people who run their PCs with no i/o cover for years and never have a problem. So is there a big risk here? A small risk? Or no real risk at all?

And if there is a risk, what could I do to give this plastic cover the same EM protection that a metal cover would give? Is there something metal that I could stick to the back or something?

Thanks in advance for any advice/suggestions!!