Just wanted to make this knowledge public since we'd discussed this a while ago. This is going to be a long post just FYI.

I run distilled + 3 drops PT Nuke (Copper Sulfate) in my loop.

I bought a FC6970 EN (the "fixed" ones) sometime in the September-October time frame when I upgraded to 2x6950 2GBs. At the time I was using one EN block and one non-EN block (purchased used). When I tore down my system, I found that the non-EN block was perfect, but the EN block had spotting on it. So I sold the non-EN block and contacted EK for help with my spotting/potential corrosion issue (the non-EN block started to corrode a few months after I sold it, so in all I think it lasted about 2 years total).

I contacted EK (which is somewhat of a pain - they're located in Slovenia which is like 7-9 hours ahead of EST) and this is the conversation that took place:

Nov 30 2011, 11:49 PM

Hi there,

I took apart my watercooled 6950s and found that my EN-plated FC6970 Nickel/Plexi waterblock has what looks like corrosion spots on it. I don't know what the procedure is for me to RMA an EN block, so that's why I created a ticket.

(had regular photographs here - could clearly see spotting but couldn't tell what it was. Might be able to find old photos)

Dec 1 2011, 8:28 AM

In order to reassure you, I have to say this does not look like a corrosion, but rather a filth from system stuck on block surface.

You may clean the block if it bothers you. It certainly will not have any influence on performance.

Several emails took place that aren't kept in the system. What basically went down was:

-I asked what I was supposed to clean it with - they told me some kind of high-end auto wax that I can't afford :/

-Took pictures of the block with a microscope - will try to find the pictures, but they're perfect circles, which is how both corrosion and deposits start initially. They were monochrome, so no indication if the copper was showing or anything.

-EK tells me that they can look at it if I pay for shipping (which is ~$13 using a small Priority Flate rate). I send it off, should get there in 6-10 days.

-

One month later (almost exactly 30 days) it arrives (screw you USPS); one of the guys fricking went on vacation in this time. Easily the most frustrating part.

-They clean it off; no corrosion found. Shipped it back to me and got here within 2 weeks.

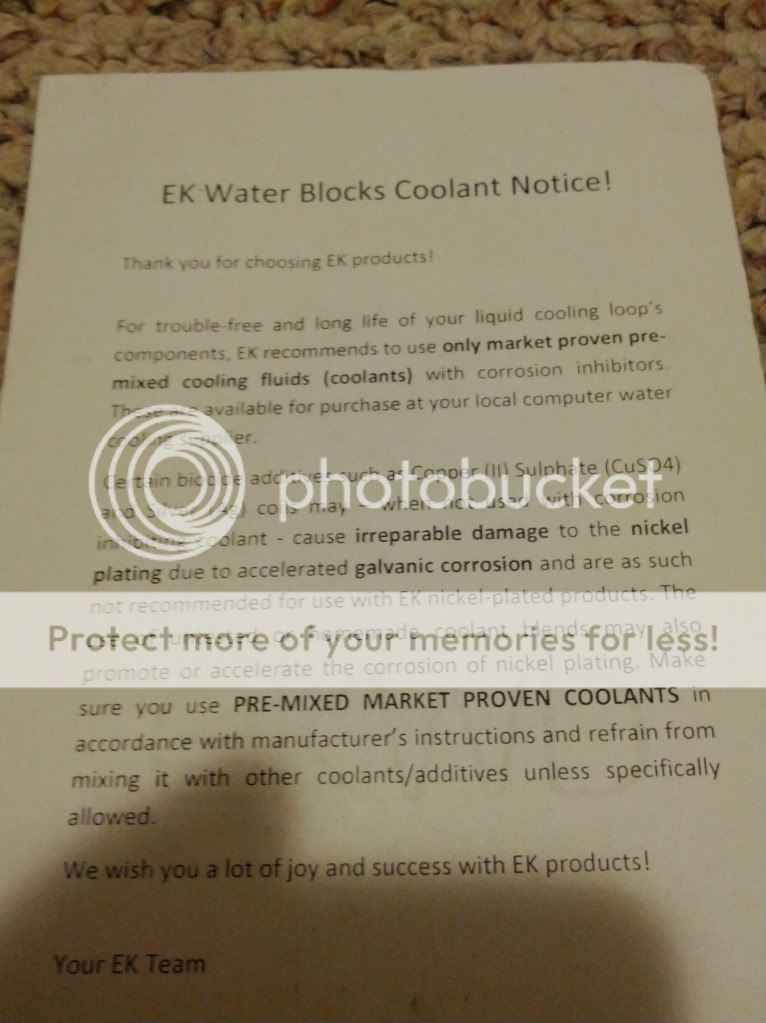

So why did I write this long a** post? Well, I got the block back (in January) with this nice little pamphlet telling me that any coolant other than a premix is damaging to EK's nickel blocks. They say that silver coils or copper sulfate (PT Nuke) can cause galvanic corrosion. As we saw in the report they issued, this is a total crock since they were having issues with just plain distilled water. Make of this what you will, but it turned me off to their nickel products, and maybe even the rest of their products.

Suggestions:

-Don't buy EK's Nickel blocks until they figure this crap out. Everybody else can make nickel-plated blocks without a problem, so what's going on here?

-In general, I wouldn't buy their products. I'm not one of those "The customer is always right" people (since a lot of people are stupid), but if a large portion of your target market thinks you're wrong based on experience (i.e. the pamphlet I posted), you shouldn't be getting our money. I'm moving to XSPC and Swiftech for future purchases.

-EK needs to open a US distribution center or something. There's no reason I should have to ship it to Slovenia in the event of a problem. Too many things can go wrong shipping internationally, and it's expensive for everybody. It's also really hard to fix and issue when I wake up in the morning to send an email and it's already evening in Slovenia - it took me about a week before I sent it in because we could only send/receive one email per day

-EK's customer service - keep doing what you're doing. It was a pleasure to deal with them, but the entire combination of issues was overall negative. I've dealt with a lot of terrible CS in the past, and EK was stellar (it was similar to my experiences with EVGA).