Hello everyone

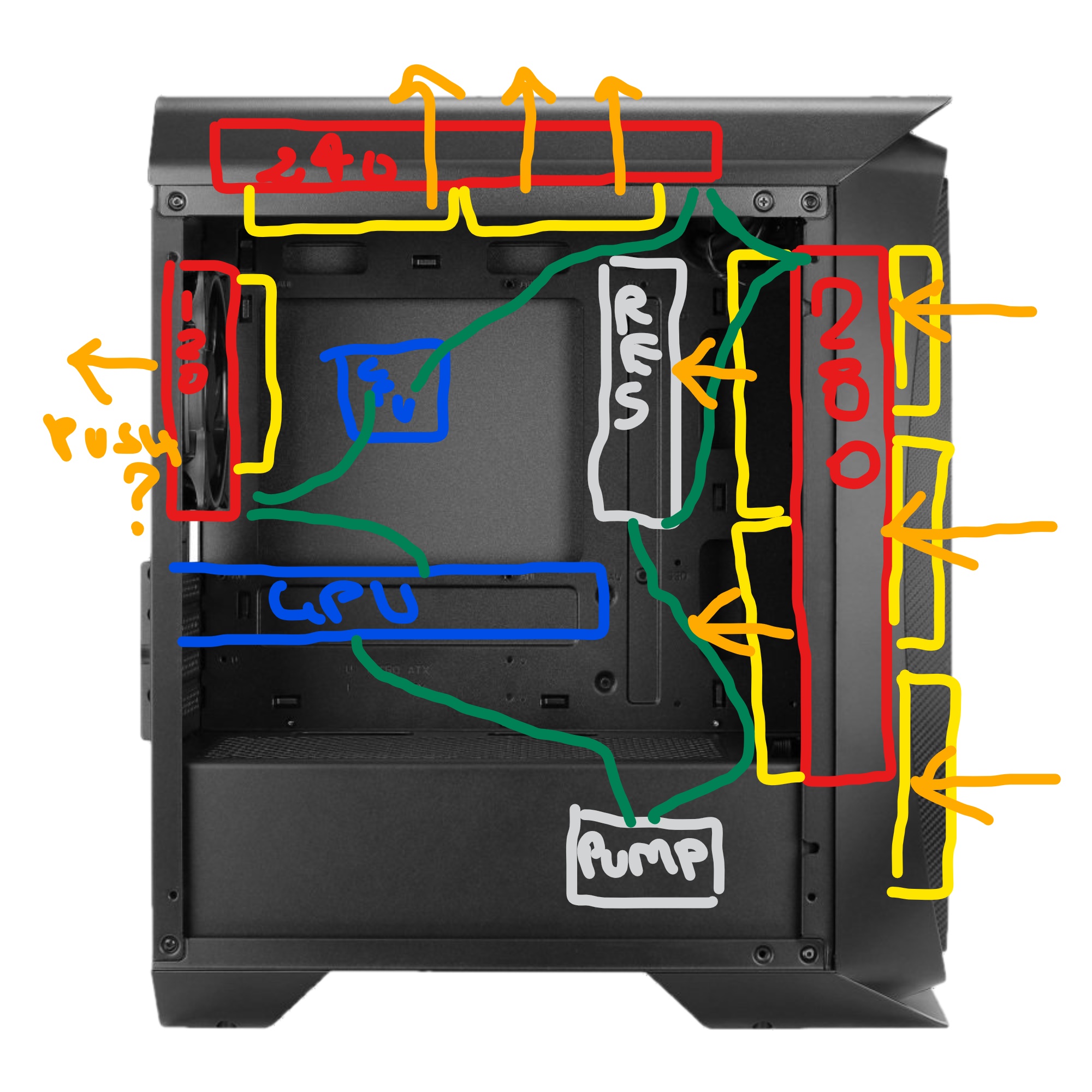

I have a custom loop of CPU and GPU cooled by 3 rads:

1x120mm on the rear

1x280mm on the top

1x240mm on thr front

I was looking for the best way to set up my custom loop to achieve the best performance possible for both CPU and GPU

As far as I know by reading some articles, best would be

Reservoir -> pump -> GPU -> CPU -> Rads -> Reservoir

Or

Reservoir -> pump -> biggest rad -> GPU -> smallest rad -> CPU -> last rad -> reservoir

What would be the best way?

Also what is the best way to mount the fans onto the rads?

For example now I have

120mm rad on the rear with fan pushing/exhaust

280mm rad on the top with fans pushing/exhaust

240mm rad on the front with pushing/intake

Would you suggest a different configuration?

at the moment this is what I have in mind

I have a custom loop of CPU and GPU cooled by 3 rads:

1x120mm on the rear

1x280mm on the top

1x240mm on thr front

I was looking for the best way to set up my custom loop to achieve the best performance possible for both CPU and GPU

As far as I know by reading some articles, best would be

Reservoir -> pump -> GPU -> CPU -> Rads -> Reservoir

Or

Reservoir -> pump -> biggest rad -> GPU -> smallest rad -> CPU -> last rad -> reservoir

What would be the best way?

Also what is the best way to mount the fans onto the rads?

For example now I have

120mm rad on the rear with fan pushing/exhaust

280mm rad on the top with fans pushing/exhaust

240mm rad on the front with pushing/intake

Would you suggest a different configuration?

at the moment this is what I have in mind