Hello everyone.

I have been reading toms hardware for a long time now and found a lot of useful info on this forum, but now im going into a more serious project and i would like some opinions and suggestions on a watercooling project that i am about to start.

What i want to make is a water cooling system that will cool a heavily overclocked i5-2500k and 2 asus 560ti cards, also overclocked but not a lot, these things are pretty un clockable. What i want is a "universal" water cooling system that i can put into a future pc with minimal hustle and expense.

The components i would like to use in the pc are:

-EK Supremacy Nickel or Copper CPU block

-EK Something Nickel or Copper universal VGA block

-Passive copper memory coolers, the small ones you buy anywhere and glue them to the ram chips, and 1 or two low rpm fans to push air onto the VGA boards and cool everything that the water block doesnt.

-1/2"fittings with 7/16 tubes

My first line of questions about the things in the pc:

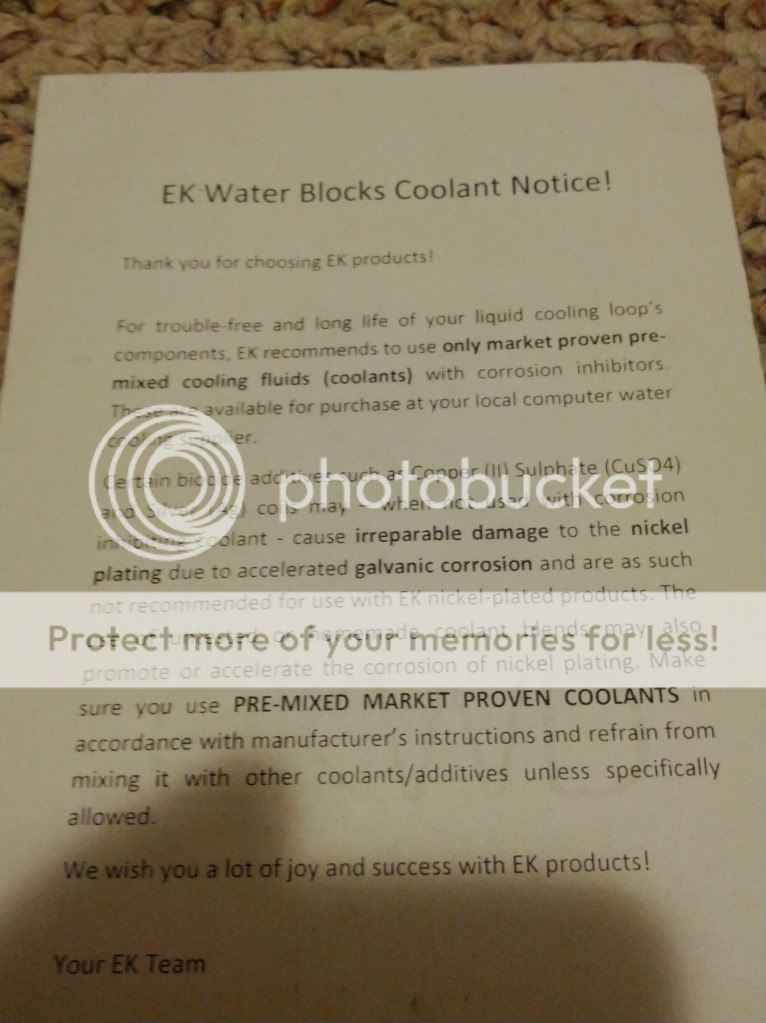

I have read that EK-s nickel series is total crap, and then in some newer posts i have read that they fixed that corrosion or whatever problem it had. What is the truth about this, is the nickel to be avoided or is it ok? And anyway, thats not a full nickel cooler but a nickel finish on a copper block right?

I have set my mind on the universal coolers since i dont want to throw a lot of money away on hi performance full blocks for 2 gpus that are outdated and will be gone in a year or two. What i want is to eliminate the tremendous amount of noise the dual coolers of the ASUS Direct CU2 cooling solution are produceing.

I'm pretty sure that i will be able to clock the gpus at a Ghz (830stock) with a little voltage and luck and have a 25% performance increase and with it about half a year of gpu power more...

The gpu clock tough is not concerning me but the memory and other pcb elements are.

Would those small passive coolers (with fans blowin in them from the sides) be sufficient to cool the memory and should i maybe install those same passive coolers on the voltage regulators and other PCB components that run hot?

Now we come to the more interesting part of my project, the external car radiator box.

So, as any idiot i have my mind pretty set on the car rad since the huge performance and unbeliveably low cost. I dont want to thorw 200e away on 2x420 rads when i can buy the big guy for less than 50.

I have read the sticky, and a load of old car rad posts and projects.

For the corrosion problem i plan to add 3/10 of antifrezze to the distiled water coolant and take my chance with it. If things corrode, ill trash it all and get wiser, but now im up to trying it.

I may even add some zinc if i find a place for it in the system, to act as the cathode instead of the aluminium rad, thats what i read on a older topic.

The rad will be a alluminium one, from a bmw or somthing, the big one not the cabin or transmission oil babys.

The vent will be also the cars vent and it will be blowing in that rad.

The whole rad box will be extiriorly mounted , so they will be on the balcony while me and the pc sit in the living room and enjoy a cool and noise free environment

I have made a small sketch of the pc, wall and radbox setup and attached a picture of my pc interior. I am new so i cant attach pictures, just the links ... :S

http://imageshack.com/i/0495821110201172164843110j

http://imageshack.com/i/5vur0j

As you can see the case is a cheap cooler master normal tower and isnt very roomy, but i think the things i want to put in will fit.

To the sketch. As you can see (barely i guess) on the lft side my pc stands behind a tv on a tv stand 50cm high. 10cm behind it is a 25cm thick wall, and behind that is the balcony. The radbox should be mounted on the other side of the wall,at the same hight as the pc.

The plumbing would go from the rad trough the wall, to the wall side of the pc, then bend, make a loop trough the components and then back trough the wall to the rad. I guess the run wouldnt bee longer than 5m, including the 1m of rad.

Ok now come the hardcore questions (excuse the borg style questioning, there's a lot of them, its most efficient this way :

:

-Should i use 1 big pump on one side of the radiator, or two smallers ones on both ends?

-What kind of characteristics should these pumps have? I dont think i will have the cash for the pumps you guys use because i live in Montenegro and have hight shipping costs and taxes, and thus will go for 2 car fuel pumps or some general usage pumps i find localy. I know that car pumps opperate at 3-3.5 bar pressure, and thats if im not mistaken as some of the hi end watercooling pumps, but thats all i know for now. What kind of performance would the pumps need to have, l/h, meters, rpms, bla bla ...

-What kind of loop should i build on this kind of system. My tought on this is rad>pump>cpu>y(parallel)>GPU1&2>t>tank>rad, but i would like to hear some more expirienced opinions on this. Would it be better to go serial or full parallel?

-The 6-7 i forgot, feel fre to answer them too

Well that s about it i guess, that's the general idea, now i would like to hear some opinions and suggestions on the matter.

Btw, i have read the sticky and am no noobie in computer hardware. I've been building pcs, cooling them and clocking them for about ten years, so dont go soft on me, but im a first timer in water cooling and i would like to fool proof this plan before i set it in motion.

Thanks In forward.

Petar Lagator

I have been reading toms hardware for a long time now and found a lot of useful info on this forum, but now im going into a more serious project and i would like some opinions and suggestions on a watercooling project that i am about to start.

What i want to make is a water cooling system that will cool a heavily overclocked i5-2500k and 2 asus 560ti cards, also overclocked but not a lot, these things are pretty un clockable. What i want is a "universal" water cooling system that i can put into a future pc with minimal hustle and expense.

The components i would like to use in the pc are:

-EK Supremacy Nickel or Copper CPU block

-EK Something Nickel or Copper universal VGA block

-Passive copper memory coolers, the small ones you buy anywhere and glue them to the ram chips, and 1 or two low rpm fans to push air onto the VGA boards and cool everything that the water block doesnt.

-1/2"fittings with 7/16 tubes

My first line of questions about the things in the pc:

I have read that EK-s nickel series is total crap, and then in some newer posts i have read that they fixed that corrosion or whatever problem it had. What is the truth about this, is the nickel to be avoided or is it ok? And anyway, thats not a full nickel cooler but a nickel finish on a copper block right?

I have set my mind on the universal coolers since i dont want to throw a lot of money away on hi performance full blocks for 2 gpus that are outdated and will be gone in a year or two. What i want is to eliminate the tremendous amount of noise the dual coolers of the ASUS Direct CU2 cooling solution are produceing.

I'm pretty sure that i will be able to clock the gpus at a Ghz (830stock) with a little voltage and luck and have a 25% performance increase and with it about half a year of gpu power more...

The gpu clock tough is not concerning me but the memory and other pcb elements are.

Would those small passive coolers (with fans blowin in them from the sides) be sufficient to cool the memory and should i maybe install those same passive coolers on the voltage regulators and other PCB components that run hot?

Now we come to the more interesting part of my project, the external car radiator box.

So, as any idiot i have my mind pretty set on the car rad since the huge performance and unbeliveably low cost. I dont want to thorw 200e away on 2x420 rads when i can buy the big guy for less than 50.

I have read the sticky, and a load of old car rad posts and projects.

For the corrosion problem i plan to add 3/10 of antifrezze to the distiled water coolant and take my chance with it. If things corrode, ill trash it all and get wiser, but now im up to trying it.

I may even add some zinc if i find a place for it in the system, to act as the cathode instead of the aluminium rad, thats what i read on a older topic.

The rad will be a alluminium one, from a bmw or somthing, the big one not the cabin or transmission oil babys.

The vent will be also the cars vent and it will be blowing in that rad.

The whole rad box will be extiriorly mounted , so they will be on the balcony while me and the pc sit in the living room and enjoy a cool and noise free environment

I have made a small sketch of the pc, wall and radbox setup and attached a picture of my pc interior. I am new so i cant attach pictures, just the links ... :S

http://imageshack.com/i/0495821110201172164843110j

http://imageshack.com/i/5vur0j

As you can see the case is a cheap cooler master normal tower and isnt very roomy, but i think the things i want to put in will fit.

To the sketch. As you can see (barely i guess) on the lft side my pc stands behind a tv on a tv stand 50cm high. 10cm behind it is a 25cm thick wall, and behind that is the balcony. The radbox should be mounted on the other side of the wall,at the same hight as the pc.

The plumbing would go from the rad trough the wall, to the wall side of the pc, then bend, make a loop trough the components and then back trough the wall to the rad. I guess the run wouldnt bee longer than 5m, including the 1m of rad.

Ok now come the hardcore questions (excuse the borg style questioning, there's a lot of them, its most efficient this way

:

:-Should i use 1 big pump on one side of the radiator, or two smallers ones on both ends?

-What kind of characteristics should these pumps have? I dont think i will have the cash for the pumps you guys use because i live in Montenegro and have hight shipping costs and taxes, and thus will go for 2 car fuel pumps or some general usage pumps i find localy. I know that car pumps opperate at 3-3.5 bar pressure, and thats if im not mistaken as some of the hi end watercooling pumps, but thats all i know for now. What kind of performance would the pumps need to have, l/h, meters, rpms, bla bla ...

-What kind of loop should i build on this kind of system. My tought on this is rad>pump>cpu>y(parallel)>GPU1&2>t>tank>rad, but i would like to hear some more expirienced opinions on this. Would it be better to go serial or full parallel?

-The 6-7 i forgot, feel fre to answer them too

Well that s about it i guess, that's the general idea, now i would like to hear some opinions and suggestions on the matter.

Btw, i have read the sticky and am no noobie in computer hardware. I've been building pcs, cooling them and clocking them for about ten years, so dont go soft on me, but im a first timer in water cooling and i would like to fool proof this plan before i set it in motion.

Thanks In forward.

Petar Lagator