This is my first thread on TH so I won’t bore anyone with the life story or rig setup. Just though this was a simple solution to an inherent problem with PCB mounted M.2. This is especially true if you have a graphics card sitting directly over top of the thing (like I do).

Installed it and got it working (google and manufacture manuals are great for this). As expected the temps in static air where horrible. I don’t have a fancy FLIR but when any no-contact thermometer reads 103C on electronics you know you have to fix that.

I peeled the sticker off so I could start getting things done. The controller and the other little chip (I dunno what it is) were a thinner BGA package than the mem. Sooo, I cut some perforated spacer to level up things for the heatsink.

The stuff I used in the previous pic is really meant to be used as is without any kind of adhesive or compound but that didn’t stop me from using any. Ultra-fine copper mesh works just as well, but tends to have stray “fibers” if you’re not careful.

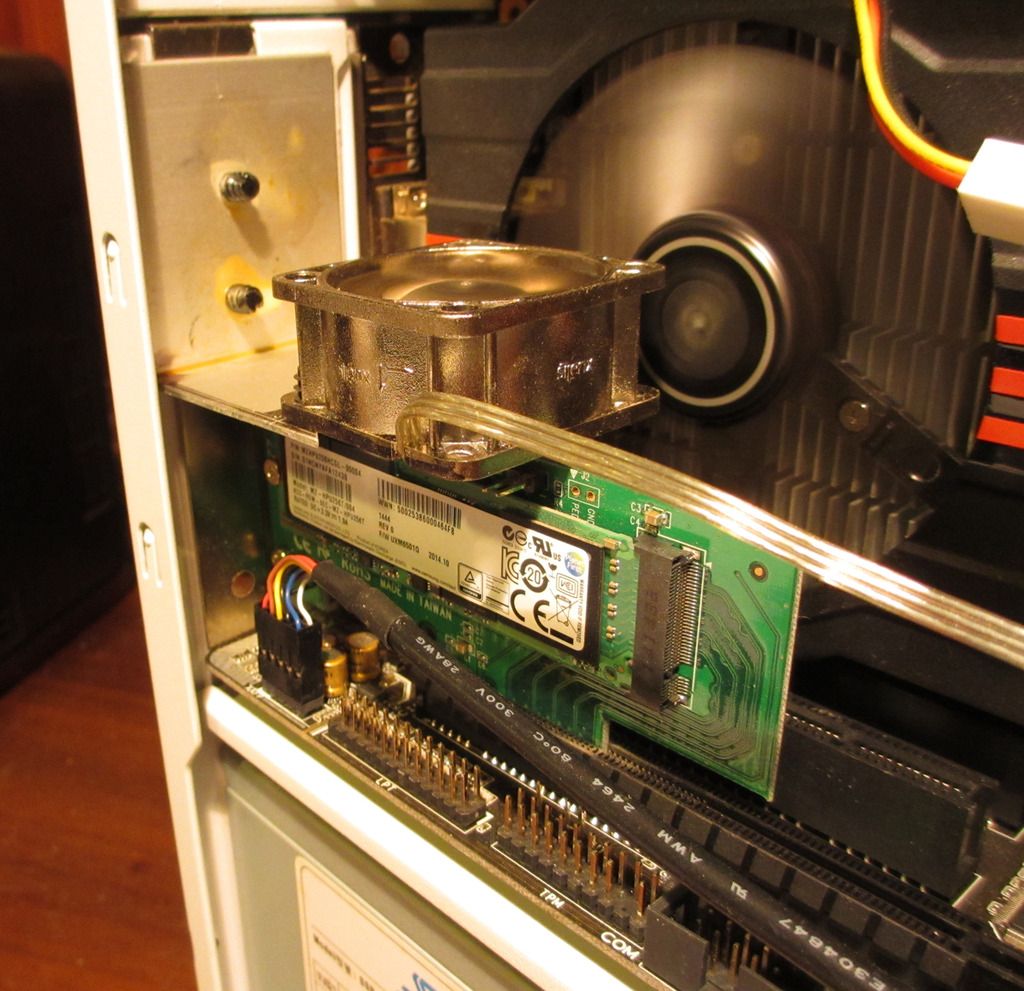

I rummaged around in the bin until I found a piece of heatsink that looked right and cut it to fit (2.75”L x 1”W x .225”H btw). Funny thing is I had gone this far with no thought whatsoever as to how I was going to keep the heatsink in place. A trip to the plumbing section at the hardware store took care of that (O-rings can you believe it? How freaking simple/easy can you get). I just made sure I had one over each chip/section so as not to put undue stress on the rather thin PCB and apply even pressure.

I will note that this heatsink has a non-conductive coating on it so I was not too worried about anything touching. An insulating film could easily be cut to fit if needed.

Can you guess what kind of motherboard I have?

Idle temps where about 38C~40C

Making it hot

Sweet!

Cool (literally compared to 100C+)

And here is the great part. Since PCIE and M.2 are fairly standard this methodology could be applied to any PCB mounted M.2.

I’m sure there is a snazzier way of doing this, but I didn’t want anything to be permanently attached on the off chance I felt like dealing with a warranty claim.

If anyone has a more "professional" and also still non-permanent way of doing this i'm all ears.

Installed it and got it working (google and manufacture manuals are great for this). As expected the temps in static air where horrible. I don’t have a fancy FLIR but when any no-contact thermometer reads 103C on electronics you know you have to fix that.

I peeled the sticker off so I could start getting things done. The controller and the other little chip (I dunno what it is) were a thinner BGA package than the mem. Sooo, I cut some perforated spacer to level up things for the heatsink.

The stuff I used in the previous pic is really meant to be used as is without any kind of adhesive or compound but that didn’t stop me from using any. Ultra-fine copper mesh works just as well, but tends to have stray “fibers” if you’re not careful.

I rummaged around in the bin until I found a piece of heatsink that looked right and cut it to fit (2.75”L x 1”W x .225”H btw). Funny thing is I had gone this far with no thought whatsoever as to how I was going to keep the heatsink in place. A trip to the plumbing section at the hardware store took care of that (O-rings can you believe it? How freaking simple/easy can you get). I just made sure I had one over each chip/section so as not to put undue stress on the rather thin PCB and apply even pressure.

I will note that this heatsink has a non-conductive coating on it so I was not too worried about anything touching. An insulating film could easily be cut to fit if needed.

Can you guess what kind of motherboard I have?

Idle temps where about 38C~40C

Making it hot

Sweet!

Cool (literally compared to 100C+)

And here is the great part. Since PCIE and M.2 are fairly standard this methodology could be applied to any PCB mounted M.2.

I’m sure there is a snazzier way of doing this, but I didn’t want anything to be permanently attached on the off chance I felt like dealing with a warranty claim.

If anyone has a more "professional" and also still non-permanent way of doing this i'm all ears.