I actually had some 300-series (nonmagnetic) stainless computer screws and absolutely

hated them. They obviously wouldn't stick to my magnetized screwdrivers so would keep falling off at inopportune times, and were

soft. It should be pretty obvious that brass screws also wouldn't stick to magnets either, so most screws are in fact mild steel that has been copper-plated and then nickel-plated, which you can check with a file. Magnetic 400-series stainless would work too, especially if screwed into brass. In general stainless-to-stainless is frowned upon unless you use an anti-seize type compound in between, because stainless galls so easily to itself.

Standoffs are often unplated brass but then you usually have a lot of free space around them when installing those, so you start them with your fingers anyway. Brass can be work hardened to about as strong as mild steel--the iron age came about because steel was more abundant and could be hardened far more and with less labor using heat. You can only anneal (soften) brass with heat.

OP is probably more interested in

harder screws that can both handle more torque without stripping and won't round off the drive end. They can get replacements in hardened carbon steel (including hardened stainless) at a local screw products store or order the following sizes online:

#6-32 UNC is the standard "coarse thread" computer screw for HDD and PSUs

M3 metric screw is the "fine thread" computer screw for optical and floppy drives

#4-40 UNC are usually only used for the thumbscrews on DVI ports and such but I've seen it on heatsinks

Standoffs are more tricky as the tops will generally be #6-32 UNC or M3 while the bottoms can be about anything. As mentioned, they can also vary considerably in height.

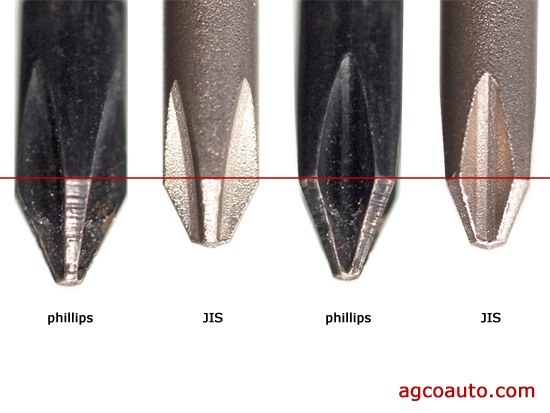

I will say, that if the primary reason OP is looking for better screws is because of mangled screw heads, a dot on the screw head indicates it

isn't Phillips at all but JIS. Get a JIS screwdriver and your problem will be solved.