Introduction

Welcome to the world of watercooling.

This guide is meant for those looking to get into watercooling or considering it as a cooling option and hobby. There is an incredible amount of information around the web and I am going to make an effort to consolidate as much as I can to help provide an encompassing guide to help as much as possible. This guide is updated as needed; please reference the update notes (link) for additional details.

Watercooling isn't simply just a cooling solution; it's just as much of a hobby for most of us. The concept of adding water into a box full of electronics seems foolish for most, very uncertain for many, and for the rest of us who do watercool... we wouldn't consider any other cooling solution. Watercooling works very similar to the cooling system in your car; the water pump circulates the water through the channels to various components that are producing heat. Water absorbs heat from a CPU block, video card block and other components, continues through connected tubing and moves to the radiator where air is forced through, cooling the water as it passes through multiple, narrow channels. The water continuously circulated throughout the loop for the process to continue. The main difference is that the water in your waterloop is typically running only 10-12C higher than ambient air temperatures and low pressure vs. near boiling and high pressures present in a car cooling system.

Watercoolers typically classify water or liquid cooling into 2 major subcategories of watercooling solutions:

1) 'Real' watercooling; consisting of a pump, waterblocks, tubing, radiator and often a reservoir; all of which can be mixed and matched with any other components to create a loop for your specific application. The pump is the metaphorical heart of your loop and typically all other components are chosen around this single component. We will cover pump info a bit later.

2) The introduction of the all-in-one or closed loop coolers over the past few years like the Corsair H50/H60/H70/H80/H100, Antec Kuhler H2O 620/920 products and other similarly designed pump/block/rad combos are products aimed at the novice who simply wants a simple, decent performing compact cooler with the added benefit of containing liquid coolant. Most of these coolers employ concepts used in full watercooling loops, but often with the cooling performance of moderate to high-end air coolers. Please see the section later in the sticky for more information on closed loop coolers.

Before you read much further, you'll need to determine your budget; this is one of the biggest factors in determining the right watercooling solution for you. It would also be incredibly wise to consider reading through 4ryan6's thread for air & watercooling initial questions:

Air Cooling vs Water Cooling : Things You Need To Know.

####################################################

Caution: When replacing the stock CPU air cooler with a water block you are removing the provided cooling to the motherboards voltage regulators, that air flow needs to be substituted with either a direct downdraft cooling fan, or increasing airflow over the entire area.

Neither the stand alone water block, nor the Pump/Block of a closed loop cooler replaces this needed airflow to cool the motherboards voltage regulators, neglecting to do this will shorten the life of your motherboard and in the overclocker's case, could shorten it significantly.

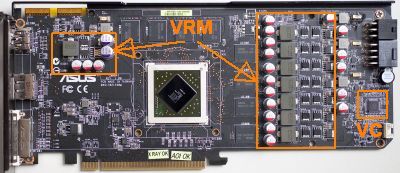

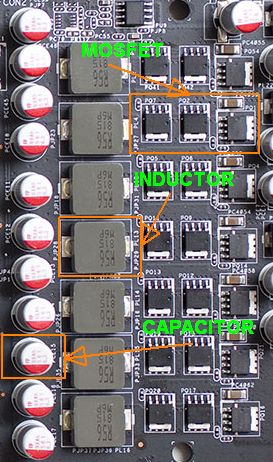

This is also true for using universal video card blocks as well. These cards rely on the stock air cooler to also cool vRAM, VRMs and MOSFETs on the PCB. When removed, they no longer have the heatsink to provide cooling they need and the addition of heatsinks will be needed to account for this. Also, good airflow is needed to adequately cool the added heatsinks, as well.

####################################################

Deciding on watercooling appeals to many people, but most aren't aware of the costs of getting started. Depending on expectations, you might determine it's not something that is needed. Here is how we typically determine budget/performance needs for a CPU-only cooling solution:

Less than $100 budget- Your best bet will likely be a good air cooler for your CPU. You can often find several closed loop coolers (LCS -liquid cooling system) in this price range. As mentioned before, most perform on-par with good to very good air coolers.

More than $100, less that $200- The XSPC and EK kits are some of the best values for the cost for a novice watercooler. They start in the $130 price range on most e-tailer sites and offer considerable performance for the cost. Swiftech Drive and Edge kits also can fall into this price range. Newcomer additions like the Swiftech H220/240-X and the EK Predator combine great, compact pumps with a solid radiator in a closed loop cooler package that is also expandable. In many kits, often there are price premiums for radiator or pump upgrades. It is also quite possible to piece together a custom loop for under $200. Recommended watercooling kits are linked below and discussed later in the sticky.

Welcome to the world of watercooling.

This guide is meant for those looking to get into watercooling or considering it as a cooling option and hobby. There is an incredible amount of information around the web and I am going to make an effort to consolidate as much as I can to help provide an encompassing guide to help as much as possible. This guide is updated as needed; please reference the update notes (link) for additional details.

Watercooling isn't simply just a cooling solution; it's just as much of a hobby for most of us. The concept of adding water into a box full of electronics seems foolish for most, very uncertain for many, and for the rest of us who do watercool... we wouldn't consider any other cooling solution. Watercooling works very similar to the cooling system in your car; the water pump circulates the water through the channels to various components that are producing heat. Water absorbs heat from a CPU block, video card block and other components, continues through connected tubing and moves to the radiator where air is forced through, cooling the water as it passes through multiple, narrow channels. The water continuously circulated throughout the loop for the process to continue. The main difference is that the water in your waterloop is typically running only 10-12C higher than ambient air temperatures and low pressure vs. near boiling and high pressures present in a car cooling system.

Watercoolers typically classify water or liquid cooling into 2 major subcategories of watercooling solutions:

1) 'Real' watercooling; consisting of a pump, waterblocks, tubing, radiator and often a reservoir; all of which can be mixed and matched with any other components to create a loop for your specific application. The pump is the metaphorical heart of your loop and typically all other components are chosen around this single component. We will cover pump info a bit later.

2) The introduction of the all-in-one or closed loop coolers over the past few years like the Corsair H50/H60/H70/H80/H100, Antec Kuhler H2O 620/920 products and other similarly designed pump/block/rad combos are products aimed at the novice who simply wants a simple, decent performing compact cooler with the added benefit of containing liquid coolant. Most of these coolers employ concepts used in full watercooling loops, but often with the cooling performance of moderate to high-end air coolers. Please see the section later in the sticky for more information on closed loop coolers.

Before you read much further, you'll need to determine your budget; this is one of the biggest factors in determining the right watercooling solution for you. It would also be incredibly wise to consider reading through 4ryan6's thread for air & watercooling initial questions:

Air Cooling vs Water Cooling : Things You Need To Know.

####################################################

Caution: When replacing the stock CPU air cooler with a water block you are removing the provided cooling to the motherboards voltage regulators, that air flow needs to be substituted with either a direct downdraft cooling fan, or increasing airflow over the entire area.

Neither the stand alone water block, nor the Pump/Block of a closed loop cooler replaces this needed airflow to cool the motherboards voltage regulators, neglecting to do this will shorten the life of your motherboard and in the overclocker's case, could shorten it significantly.

This is also true for using universal video card blocks as well. These cards rely on the stock air cooler to also cool vRAM, VRMs and MOSFETs on the PCB. When removed, they no longer have the heatsink to provide cooling they need and the addition of heatsinks will be needed to account for this. Also, good airflow is needed to adequately cool the added heatsinks, as well.

####################################################

Deciding on watercooling appeals to many people, but most aren't aware of the costs of getting started. Depending on expectations, you might determine it's not something that is needed. Here is how we typically determine budget/performance needs for a CPU-only cooling solution:

Less than $100 budget- Your best bet will likely be a good air cooler for your CPU. You can often find several closed loop coolers (LCS -liquid cooling system) in this price range. As mentioned before, most perform on-par with good to very good air coolers.

More than $100, less that $200- The XSPC and EK kits are some of the best values for the cost for a novice watercooler. They start in the $130 price range on most e-tailer sites and offer considerable performance for the cost. Swiftech Drive and Edge kits also can fall into this price range. Newcomer additions like the Swiftech H220/240-X and the EK Predator combine great, compact pumps with a solid radiator in a closed loop cooler package that is also expandable. In many kits, often there are price premiums for radiator or pump upgrades. It is also quite possible to piece together a custom loop for under $200. Recommended watercooling kits are linked below and discussed later in the sticky.